The professional’s choice

- Moisture & Mold Resistant

- EdgeTech® Reinforced Edge

- Easy to Cut

- Interior and Exterior Use

PermaBASE® Cement Board provides a durable surface designed to withstand prolonged exposure to moisture. Made with Portland cement, aggregate, and fiberglass mesh, it works well as an underlayment for tub and shower surrounds, countertops, flooring, and a variety of other interior and exterior applications. Lightweight and easy to install, our EdgeTech® Technology allows a closer nail or screw application.

Advantages

- Stays intact when exposed to water; will not rot, disintegrate, or swell.

- Achieves the industry’s lowest water-absorption rating (ASTM C473).

- Helps inhibit mold growth with the highest possible score on mold tests (ASTM D3273 and ASTM G21).

- Resists impact and remains dimensionally stable.

- Holds up to toughest conditions.

- Lightweight and easy to cut – speeds up installation and reduces job site waste.

- Durable substrate for direct-applied coating systems.

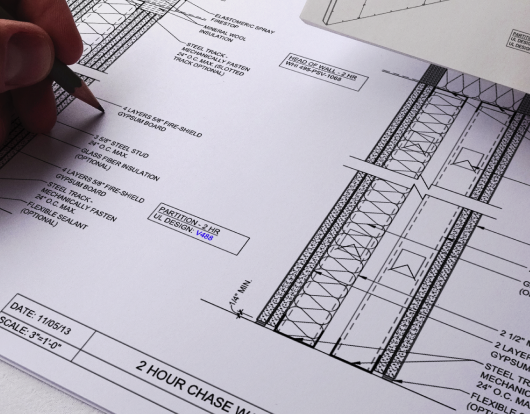

- Meets UL classifications for one-and two-hour fire-rated assemblies.

- Building code approved – one substrate that does the job of many.

Interior Applications

- For interior application information, click here.

- Lifetime Limited Warranty for Residential Interior applications.

Exterior Applications

- For exterior application information, click here.

- 15-year Limited Warranty for Exterior applications.

GREENGUARD Certified

PermaBASE® Cement Board has achieved UL GREENGUARD Gold Certification.

Specifications

Products that suit any project criteria

Product Details

Project Area:

Shower, Sauna / Steam Room, Heat Shield, Kitchen, Floors, Bathtub, Accent Wall, Outdoor Living, Cement Board Masonry Veneer, Cement Board Stucco, Architectural Coatings

Edge(s):

EdgeTech® Reinforced Edge

Thickness(es):

1/4", 3/8", 1/2", 5/8", 3/4", 1"

Width(s):

32", 36", 48"

Interior FAQs

What kind of fasteners do I use to install PermaBASE® Cement Board?

Corrosion-resistant screws or galvanized roofing nails. We strongly suggest PermaBASE™ Cement Board Screws.

What do I tape the PermaBASE® Cement Board joints with?

4” wide alkali-resistant PermaBASE™ Cement Board Tape for all exterior applications.

What is the depth of fastener placement in wood and metal?

Long enough to go into woods studs ¾” and metal framing 3/8” (min. three threads).

When is it acceptable to install PermaBASE® Cement Board directly to the studs?

For interior applications. For exterior jobs, PermaBASE should always be installed over a primary sheathing and furring strips.

What is the required maximum stud spacing for walls?

16” o.c for wood and metal.

What is the fastener spacing for interior wall applications?

Every 8” o.c. along the perimeter and field of board.

Exterior FAQs

What kind of fasteners do I use to install PermaBASE® Cement Board?

Corrosion-resistant screws or galvanized roofing nails. We strongly suggest PermaBASE™ Cement Board Screws.

What do I tape the PermaBASE board joints with?

3" or 4” Alkali-resistant mesh tape and polymer-modified mortar mix.

What is the depth of fastener placement in wood and metal?

Long enough to go into woods studs ¾” and metal framing 3/8” (min. three threads).

What is the height limitation for installing PermaBASE® Cement Board in the CBMV/PB system?

Low rise residential or commercial applications. Higher heights may be approved by a design professional.

Should I install the board vertically or horizontally?

Both methods are approved as long as you stagger the joints.

Related Resources

Product details and technical documentationIn

International Distributors

For International Distributors of Unifix products, click below

Explore Now

Expert Connection

Discuss your project with Unifix experts who can help guide your product selection.

Get In TouchNeed Technical Information?

Call 1-800-NATIONAL®

Unifix is the exclusive service provider for products manufactured by PermaBASE Building Products, LLC.